OPW Engineered Swivel Joints

OPW manufactures swivel joints for a broad range of uses in the chemical, petroleum, petrochemical, refining, mining, distilling, brewing, ink and paint industries, as well as farm irrigation and fertilizing. Design, plant and maintenance engineers use OPW swivel joints in flexible piping systems, loading arms, hose reels, sewer rodding and wastewater treatment equipment, and various types of process machinery. They also use our swivel joints in machine tool coolant transfer, drum filling applications, and in a variety of in-plant fluid and dry bulk transfer applications.

Versatility is the key to OPW swivel joints. They make it possible for you to use rigid metal piping for loading and unloading fluids and dry product under pressure or vacuum without the difficulty or danger of handling heavy, cumbersome hoses.

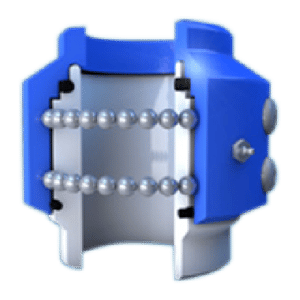

General Purpose Swivel Joints - 3000 Series

Versatility is the key to OPW swivel joints. They make it possible for you to use rigid metal piping for loading and unloading fluids and dry product under pressure or vacuum without the difficulty or danger of handling heavy, cumbersome hoses.

- Sizes: 3/4” to 12”

- Standard Materials: Aluminum, Bronze, Carbon Steel, Ductile Iron, 316 Stainless Steel

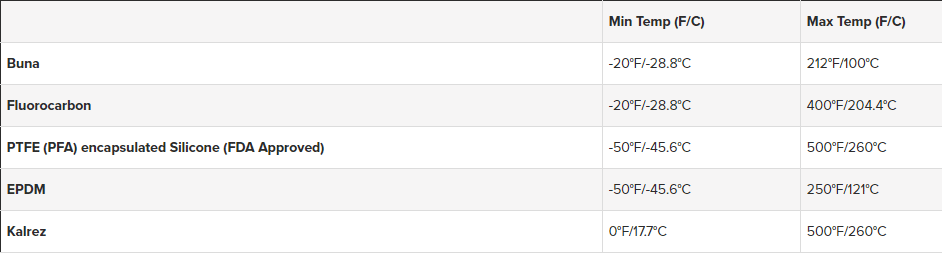

- Standard Seals: Buna-N, Fluorocarbon, PTFE, EPDM, Neoprene, Kalrez®

- End Connections: FNPT, 150/300 ANSI Flanged Ends, Butt/Socket Welds

- Aluminum (ASTM B26, A356 T6)

- Bronze ( ASTM B62-83600)

- Carbon Steel (ASTM A105)

- Ductile Iron (ASTM A-536)

- Stainless Steel (ASTM A351-CF3M/CF8M)

- Buna

- Fluorocarbon

- PTFE

- EPDM

- Neoprene

- Kalrez

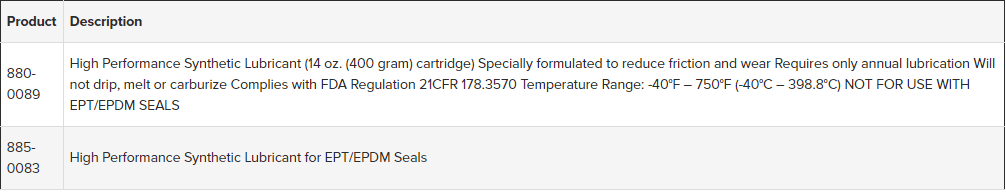

Lubrication plays an important role in the life expectancy of a swivel joint. OPW has done extensive research to determine the best lubricants for our products. Our standard is a High Performance Synthetic Lubricant (OPW part # 880-0089).

- Specially formulated to reduce friction & wear.

- Requires only annual lubrication

- Will not drip, melt or carbonize

- Complies with FDA regulation 21CFR178.3570

- Temperature Range -40F – 750F (-40C – 399C)

- Not for use with EPT/EPDM Seals. EPT/EPDM seals require the use of OPW 885-0083 lubricant.

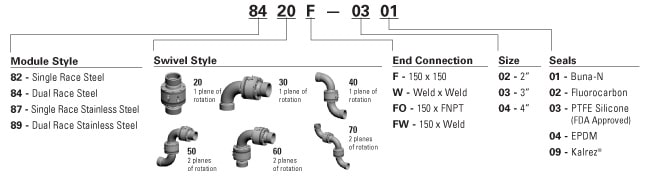

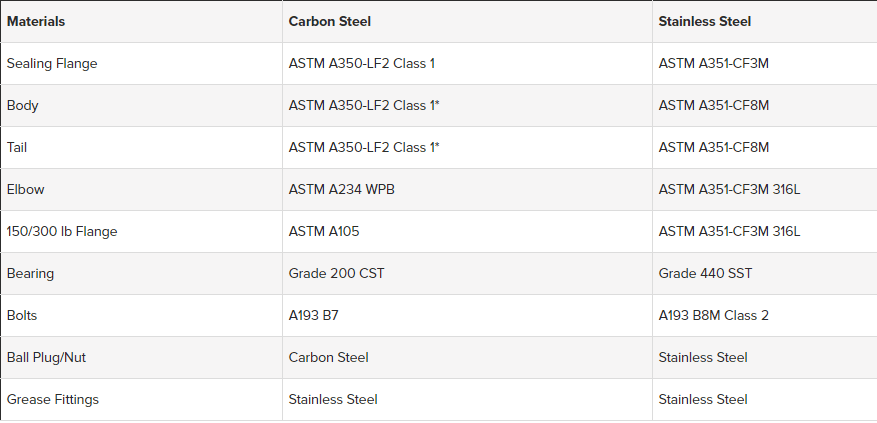

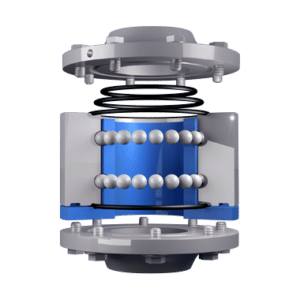

8000 Series Endura Split Flange Swivels

The Endura™ Dual Split Flange (DSF) swivel joint from OPW® Engineered Systems represents the best in swivel technology. Specifically designed for the transfer of hazardous materials such as acids, solvents, petrochemicals and other toxic fluids, Endura™ sets the standard in Loading Arm Swivel performance.

- Sizes: 2 in., 3 in., 4in.

- Standard Materials: Carbon Steel, Stainless Steel

- Standard Seals: Buna-N, Fluorocarbon, PTFE, EPDM, Neoprene

- End Connections: FNPT, 150/300 ANSI Flanges, Butt Weld

- Endurance – Heavy-duty construction and unique design features result in long-life, hassle-free operation

- Improves Uptime Performance – Endura™ DSF swivel technology, combined with the most user-friendly counterbalance solutions, results in less downtime, less labor, less cost!

- Lowest Overall Cost of Ownership – Optimized performance, downtime prevention and reduced maintenance time and costs make this the best overall loading arm solution currently available.

- Redundant Sealing – for added safety!

- Bearing Module – for easy maintenance

- Easy Maintenance – Simply unbolt sealing flanges to access seals, no ball bearings to remove

- Leak Detection Port – In the event of main seal leakage, fluid would be channeled to leak detection port; quick & easy way to monitor performance so that maintenance can be performed

- Purge Port – For critical applications, an inert gas can be injected at leak detection/purge port; inert gas pressure higher than product pressure to virtually eliminate risk of fugitive emission; recommended for your extreme applications!

Hose Reel Swivels

An integral part of many hose reel applications is an OPW Swivel Joint. OPW produces a variety of Swivel Joints designed specifically for Hose Reels. In addition, we have the ability to customize a hose reel swivel to fit your specific application.

Style 20VO Swivel Joint Aluminum Construction Standard Seals: Buna, Fluorocarbon, PTFE, EPDM, Neoprene 2” FNPT x 2½” Victaulic

Style 30VO Swivel Joint Aluminum Construction Standard Seals: Buna, Fluorocarbon, PTFE, EPDM, Neoprene 2” FNPT x 2” Victaulic

Style 3627VO Swivel Joint Aluminum Construction Standard Seals: Buna, Fluorocarbon, PTFE, EPDM, Neoprene 3” FNPT x 3” Victaulic

Style 3637VO Swivel Joint Aluminum Construction Standard Seals: Buna, Fluorocarbon, PTFE, EPDM, Neoprene 3” FNPT x 3” Victaulic

Style 30 Swivel Joint Standard Materials: Carbon Steel, 316 Stainless Steel, Aluminum Standard Seals: Buna, Fluorocarbon, PTFE, EPDM, Neoprene ¾” to 12” sizes FNPT, ANSI Flanged